Shivvers Circu-Lator Jr

Continuous Counter-Flow Drying on any budget

Shivvers' CIRCU-LATOR JR. puts continuous counter-flow grain drying within reach of any farm size or budget. The CIRCU-LATOR JR provides grain drying capacity up to 3,000 bushels per day.

Shivvers' CIRCU-LATOR JR. puts continuous counter-flow grain drying within reach of any farm size or budget. The CIRCU-LATOR JR provides grain drying capacity up to 3,000 bushels per day.

Ideal for bins with existing transfer equipment

The CIRCU-LATOR JR is ideal for existing bins where unloading equipment already exists. It’s designed to fit drying bins from 15’ to 27’ in diameter. The CIRCU-LATOR JR can be used without transfer equipment as a recirculating unit, or with transfer equipment for continuous-flow drying of most any free-flowing grain including corn, soybeans, wheat, milo, and rape.

Machine Components

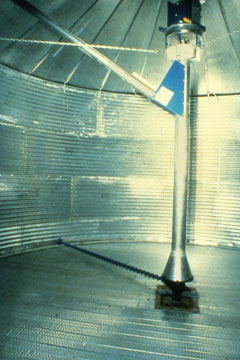

The CIRCU-LATOR JR. basic machine consists of a top-mounted motor with gear drive, recirculating grain spreader, 6” center vertical auger, heavy-duty gearbox, and a tapered sweep auger.

No Watching. No Waiting. No Waste.

By adding additional Shivvers components you can dry 24 hours a day, 7 days a week. The entire drying system is controlled automatically by either our COMPUDRY™ Command Center or economical Compact control. In using the drying tank for wet holding storage as well, surge capacity of the CIRCU-LATOR JR. is unmatched by any comparably priced cross-flow dryer.

As with a Shivvers Performance System, the drying zone of the CIRCU-LATOR JR. is at the bottom of the tank. Heated air blown into the plenum and up through the bin at floor level is forced through the wet grain and escapes at the top of the tank, 98% saturated. As the grain dries uniformly, it’s removed at floor level by a single tapered sweep auger.

Continuous Flow or Recirculation – The choice is Yours

The CIRCU-LATOR JR. can be used as a 3,000 bushel a day continuous-flow dryer when incorporated with a series of storage bins connected by additional continuous-flow augers. Used as a recirculating batch dryer, the CIRCU-LATOR JR. can dry thousands of bushels of grain at one time until it reaches the perfect quality for market or storage.

For recirculating, the sweep auger removes the dried grain in thin, even layers and moves it to the center of the bin where it travels up the center vertical auger for recirculation. If used as a continuous-flow system, the tapered sweep auger moves the grain to bin center and up the center vertical auger to transfer auger which moves it to storage.

OPTIONAL SHIVVERS LEGACY SERIES COMPONENTS

Step Up to the Performance Reliability of Shivvers Grain Drying Components.

Shivvers Legacy Series counter-flow grain drying machines provide flexibility in mixing and matching components to fit your needs. Whether your own transfer equipment and components such as drying floor or fans and heaters, or the addition of reliable Shivvers components, a solution is not far away. Shivvers' components provide the added benefit of having been tested and installed in a way that meets our rigid specifications. In this way, you can be assured of performance that meets your goal.